Applied Diamond Image & Application

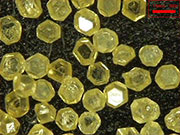

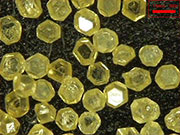

• 3D250S Diamond

- – Products designed to have a very sharp edge

- – Suitable for areas that require enhanced cutting ability and precise grinding quality.

- – Applied in grinding glass and quartz, furniture glass, and mirrors.

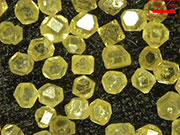

• 3D300S Diamond

- – Products with good fracturability and strength

- – Capable of continuous cutting-edge creation due to fine fragmentation by the sharp shape.

- – Suitable for areas requiring a higher surface quality than MBG-640.

- – Used for flat glass grinding, edge grinding, and cutting tasks in glass or crystal.

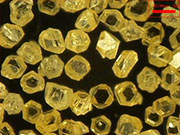

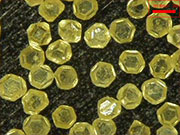

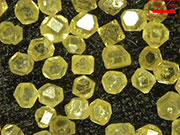

• 3D350S Diamond

Toughness index: Maintaining the initial size after impacting 2cts diamonds with a steel ball at 2400 cycles/min: 53%

Toughness index: Maintaining the initial size after impacting 2cts diamonds with a steel ball at 2400 cycles/min: 53% Thermal toughness index: After heating at 1100 degrees for 20 minutes (inert atmosphere) and cooling, ti test conducted: 42%

Thermal toughness index: After heating at 1100 degrees for 20 minutes (inert atmosphere) and cooling, ti test conducted: 42%

- – Cubo-octahedral shaped products

- – Possess high impact strength and material removal rate.

- – Applied where surface quality is demanded.

- – Used for glass processing core-drills, and external grinding of Si3N4 (Ceramics), etc.

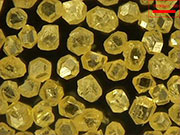

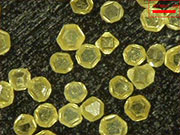

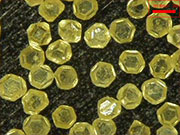

• 3D400S Diamond

- – Perfect Cubo-octahedral Shape with Top Grade Products

- – Excellent impact strength and thermal stability.

- – Applied in areas where diamonds are subject to high loads.

- – Used in the electronics industry, ferrite motor cores, and granite processing, etc.

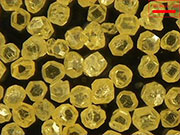

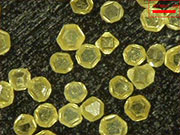

• 3D500S Diamond

- – Perfect Cubo-octahedral Shape with Top Grade Products

- – Excellent impact strength and thermal stability.

- – Applied in areas where diamonds are subject to high loads.

- – Used in the electronics industry, ferrite motor cores, and granite processing, etc.

• 3D250S Diamond

- – Products designed to have a very sharp edge

- – Suitable for areas that require enhanced cutting ability and precise grinding quality.

- – Applied in grinding glass and quartz, furniture glass, and mirrors.

• 3D300S Diamond

- – Products with good fracturability and strength

- – Capable of continuous cutting-edge creation due to fine fragmentation by the sharp shape.

- – Suitable for areas requiring a higher surface quality than MBG-640.

- – Used for flat glass grinding, edge grinding, and cutting tasks in glass or crystal.

• 3D350S Diamond

Toughness index: Maintaining the initial size after impacting 2cts diamonds with a steel ball at 2400 cycles/min: 53%

Toughness index: Maintaining the initial size after impacting 2cts diamonds with a steel ball at 2400 cycles/min: 53% Thermal toughness index: After heating at 1100 degrees for 20 minutes (inert atmosphere) and cooling, ti test conducted: 42%

Thermal toughness index: After heating at 1100 degrees for 20 minutes (inert atmosphere) and cooling, ti test conducted: 42%

- – Cubo-octahedral shaped products

- – Possess high impact strength and material removal rate.

- – Applied where surface quality is demanded.

- – Used for glass processing core-drills, and external grinding of Si3N4 (Ceramics), etc.

• 3D400S Diamond

- – Perfect Cubo-octahedral Shape with Top Grade Products

- – Excellent impact strength and thermal stability.

- – Applied in areas where diamonds are subject to high loads.

- – Used in the electronics industry, ferrite motor cores, and granite processing, etc.

• 3D500S Diamond

- – Perfect Cubo-octahedral Shape with Top Grade Products

- – Excellent impact strength and thermal stability.

- – Applied in areas where diamonds are subject to high loads.

- – Used in the electronics industry, ferrite motor cores, and granite processing, etc.